And let’s face it: Your team’s primary focus is patient care. So even if workplace safety is a priority, you may forget to cross a ‘T’ or dot an ‘I’ on precautionary measures with the demands of running a practice.

Unfortunately, this is how you find yourself on the wrong side of OSHA. The number of OSHA inspections within the industry (businesses providing veterinary services or pet care services) has risen steadily over the last five years. Being unprepared or noncompliant can result in violations and costly fines.

Not to worry though! We’ve got recommendations to help you avoid the most common compliance pitfalls and safeguard your employees’ health and wellbeing.

Invest in safety planning and document everything

Three of the top four reasons veterinary offices receive OSHA violations each year stem from documentation issues. Clinics overlook the creation of a hazard communication program, miss fire or emergency plans, skip the appropriate OSHA forms or have no record of employee training.

Safety requires intentionality, which is why OSHA mandates that practices assess their facility for hazards, take preventative measures, develop safety plans and regularly train staff on these items.

Having guidance on these requirements and the tools to meet them can eliminate time sunk into research and the stress of building programs from scratch. Patterson Veterinary Academy offers a compliance CE package tailored to this exact need. It provides in-depth education on veterinary-specific OSHA requirements and guidelines for practice compliance, as well comprehensive planning resources like:

- 20+ safety plan samples/templates

- Safety training documentation

- Small Business OSHA handbook

- OSHA 3685 and OSHA 3071 Standards

- OSHA 300 Series and Facility Hazard Assessment forms

- I2P2 fact sheet

Veterinary professionals are exposed to a large number of chemicals on a daily basis. For the safety of employees, OSHA requires practices to obtain and maintain SDSs for each hazardous substance. These include, but aren’t limited to, cleaning and maintenance chemicals, toxic gases, laboratory products, injectable drugs and non-exempt pharmaceuticals. The AVMA has resources to help you identify hazardous materials, if you’re uncertain which of your products fall in this category.

Lack of safety data sheets ranks number five on the most frequent OSHA violations. Your practice may need to upkeep a few hundred SDSs to remain compliant, and versions are subject to change at any time as manufacturers modify chemicals or concentrations.

To minimize the administrative burden on veterinary teams, Patterson offers AutoSDS. The digital SDS management system automatically uploads sheets from your Patterson-purchased products to a personalized library and lets you add SDSs from other manufacturers and distributors.

AutoSDS also improves compliance and speeds response time in emergency situations by making vital safety information readily accessible to all staff members via QR scan, workstation or any browser on a device – with a mobile app option available soon!

Make PPE a priority

Correctly utilized personal protective equipment (PPE) helps protect workers from physical and health hazards. The situation dictates the level of personal protective equipment – of which there are four, A through D – depending on risk factors. As a rule, PPE is needed when working with patients, certain medications, laboratory specimens and other substances.

Though it’s easy to purchase gear like gloves, eye and face protection, protective clothing and respiratory protective equipment from veterinary distributors, practices still get dinged by OSHA for inappropriate PPE every year. Seek durable, high-quality products and don’t forget to monitor regular wear and tear on equipment. For example, we recommend X-raying your Pivetal lead apron at least once annually to ensure there are no cracks, eliminating unexpected radiation exposure.

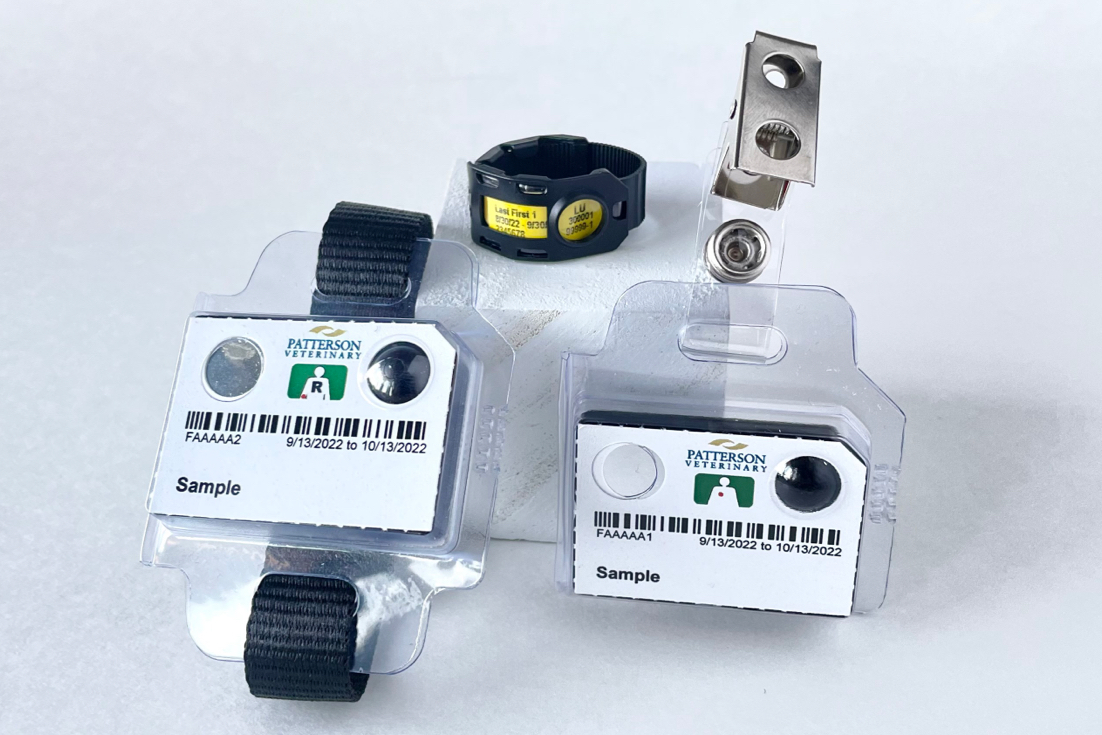

While on the topic of radiation, dosimetry monitoring should be on your list of requisite PPE. In many states, legislation requires veterinary clinics to provide staff with appropriate personal monitoring equipment when they work with occupational radiation through imaging equipment.

Patterson offers dosimeter badges as a protective tool, to keep your team safe by helping identify if, and how much, radiation a wearer received. Our service makes OSHA compliance simpler by allowing you to add and remove badge wearers, run reports, order additional badges and easily return badges for evaluation through a 24/7 online portal.

Leverage anesthesia expertise for safety

For the safety of staff, OSHA requires anesthetic gas monitoring programs for practices with employees exposed to defined quantities of isoflurane or halothane gas. But “no control of anesthetic waste gases” is a frequently cited violation. OSHA offers tips to reduce workplace gas exposure and choosing a quality anesthesia partner will help your practice meet standards. Patterson offers Anesthesia Support to provide veterinary practices with guidance from purchase to disposal. Our dedicated anesthesia team can advise on the best anesthesia systems including ventilators, vaporizers, monitors, waste gas collection or evacuation and oxygen supply equipment for a practice’s individual setup and help troubleshoot any technical issues with a unit. We also provide vaporizer exchanges, which improves staff safety when administered at the proper cadence by reducing or eliminating exposure to toxic gas.

Compliance made easy

Meeting OSHA standards within your veterinary practice shouldn’t feel stressful or unattainable. Knowing the most common issues can help you plan effectively and avoid missteps or oversights.

With the right equipment and resources, your team can confidently navigate compliance and trust safety in the workplace. Patterson has expert representatives, education, software, equipment and supplies to support all of your compliance needs.

Want more information about compliance solutions? Contact your Patterson rep!

Share

Related blogs

7 Resources to Help You Conquer Compliance

Terms like “OSHA,” “regulatory compliance,” and “hazard communication protocol” may seem intimidating, but by broadening your expertise in these key areas, you’ll find empowerment. From podcasts to webinars, these 7 resources will help you become a compliance champion.

OSHA Compliance: Examining the Foundational Role of Safety Data Sheets

TotalSDS’s Alex Milan and Veronica Marrero offer an overview of the importance of safety data sheets, including two case studies that illustrate the risk of noncompliance. Finally, they share a compelling digital safety data sheet management solution.

Top 7 Questions From our Impact of OSHA Changes Webinar

If you missed our Impact of OSHA'S Hazard Communication Standard 2024 webinar, don't worry - we got you! In this post, we're reviewing seven of the most-asked questions, as well as outlining what has recently changed.