OSHA Compliance: Examining the Foundational Role of Safety Data Sheets

OSHA’s Hazard Communication Standard (HCS) requires practices to inform employees about the hazardous chemicals they may be exposed to and provide training on how to handle them safely.

To simplify it, the standard gives your staff the right to know about the hazardous chemicals around them and the right to understand the risks of exposure to them.

There are three key pieces to the Hazard Communication Standard for practices to be mindful of:

1. Accessible safety data sheets (SDSs)

Practices must have SDSs that are always readily accessible for all hazardous chemicals used in the practice. This means that SDSs are not behind a lock or a password if accessed digitally. To enhance accessibility, many practices now use QR code posters that allow staff to quickly access digital SDS information using their smartphones.2. Staff training

Practices are required to provide full training on hazard communication to all employees who may be exposed to hazardous chemicals. The training should include specific risks for each product, proper handling techniques (wearing gloves, for example) and what to do if exposure occurs.3. Written hazard communication program

Veterinary practices are required to develop and implement a written hazard communication program that outlines how they comply with the HCS.Common non-compliance issues in veterinary practices frequently are the result of poor organization and outdated documentation. These may include:

- Unorganized or incomplete SDS binders/management systems

- Failure to update SDSs when new products are purchased

- Inadequate labeling of secondary containers (e.g., cleaning spray bottles, prefilled syringes)

- Insufficient or missing employee training records

Real-world impacts of poor SDS management

Case study 1: OSHA penalties due to unorganized SDSs

A mid-sized veterinary clinic in the Midwest faced significant OSHA penalties following a routine inspection. The clinic incurred over $20,000 in OSHA fines after an inspection revealed disorganized, outdated and inaccessible SDSs, with several missing entirely. They had to overhaul its SDS system, retrain staff and absorb unexpected downtime and costs.Case study 2: Chemical exposure incident worsened by lack of SDS access

In a small animal practice on the West Coast, a veterinary technician accidentally spilled a hazardous cleaning agent. Due to poorly organized SDSs, staff members were unable to quickly access the necessary safety information. This delayed obtaining proper first aid and handling procedures, which led to more severe chemical burns for the technician and contamination of the surrounding area. The technician required extended medical leave and the clinic faced potential legal action.Broader consequences of non-compliance

These cases highlight several critical consequences of poor SDS management.Staff injuries or illnesses: Lack of readily available safety information can lead to improper handling and storage of hazardous materials, resulting in acute injuries or long-term health effects for employees.

Liability risks and reputational damage: Incidents caused by inadequate safety practices can expose clinics to significant liability. Such events can damage a clinic’s reputation, causing client loss and staffing challenges.

Financial costs: Beyond OSHA fines, clinics may face increased insurance premiums, legal fees and costs for corrective measures. In severe cases, clinics might need to temporarily close for remediation, resulting in lost revenue.

By prioritizing SDS management, you can protect your staff, maintain regulatory compliance, and safeguard your operations against potentially devastating consequences.

Digital SDS software means compliance and accessibility

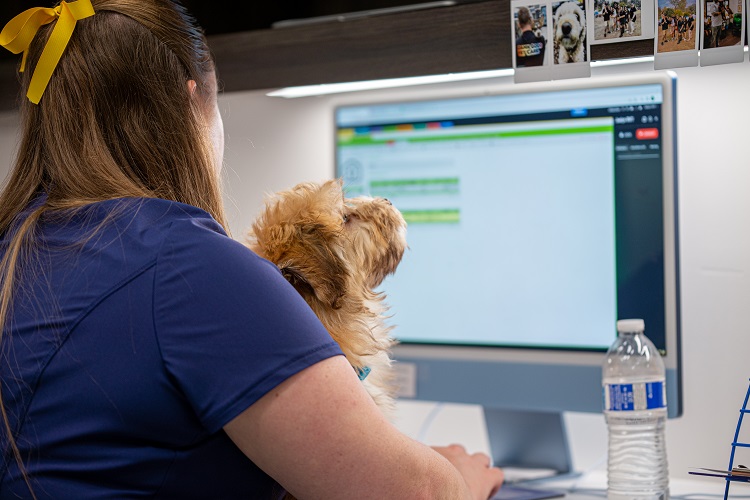

Consider transitioning to a digital SDS management system. A digital solution like AutoSDS can offer several advantages:- Improved accessibility via smartphones or tablets

- Enhanced searchability

- Easy updates and maintenance

- QR code integration for quick access

AutoSDS software. A digital safety data sheet (SDS) management solution

AutoSDS software makes chemical safety information easy to maintain and easy to access. It makes creating an OSHA-compliant hazard communication plan for your staff easier as well.The average practice uses more than 450 products in-clinic. AutoSDS software eliminates the manual labor needed to maintain safety data sheets (SDSs). Plus, it improves emergency preparedness by giving your team ready access to your practice’s custom SDS library from any workstation or mobile device – by browser, app or safety poster.

Reach out to your Patterson Veterinary representative for additional OSHA compliance solution help any time, and visit this page of our website to learn more about AutoSDS Online Safety Data Sheets.

Sources

- Occupational Safety and Health Administration. (2024). Hazard communication. 29 C.F.R. § 1910.1200(a)(1). Retrieved from osha.gov/laws-regs/interlinking/standards/1910.1200(a)(1).

- Occupational Safety and Health Administration. (2024). Hazard communication. 29 C.F.R. § 1910.1200(g)(8). Retrieved from osha.gov/laws-regs/interlinking/standards/1910.1200(g)(8).

- Occupational Safety and Health Administration. (2024). Hazard communication. 29 C.F.R. § 1910.1200(h)(1). Retrieved from osha.gov/laws-regs/interlinking/standards/1910.1200(h)(1).

Share

Related blogs

7 Resources to Help You Conquer Compliance

Terms like “OSHA,” “regulatory compliance,” and “hazard communication protocol” may seem intimidating, but by broadening your expertise in these key areas, you’ll find empowerment. From podcasts to webinars, these 7 resources will help you become a compliance champion.

Top 7 Questions From our Impact of OSHA Changes Webinar

If you missed our Impact of OSHA'S Hazard Communication Standard 2024 webinar, don't worry - we got you! In this post, we're reviewing seven of the most-asked questions, as well as outlining what has recently changed.

4 Ways to Avoid Common Compliance Pitfalls

We’ve got recommendations to help you avoid the most common OSHA compliance pitfalls and safeguard your employees’ health and wellbeing.